Iyo yakanyanya kudzvanywa die casting inzira inoita kuti mvura kana semi-mvura simbi izadze gomba rekufa rekukanda mold nekumhanya kwakanyanya nekumanikidza kwakanyanya, uye mafomu uye anoomesa pasi pekumanikidzwa kuwana kukanda.

1.High pressure casting process

1.1

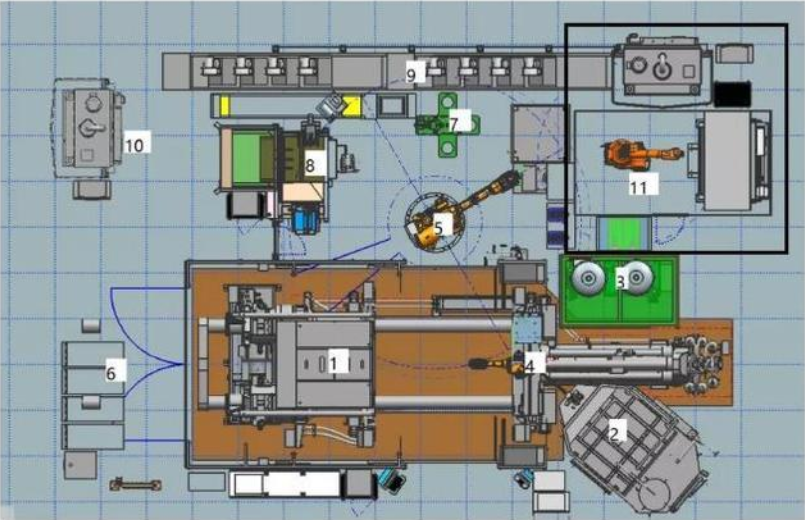

Parizvino, iyo general die-casting chitsuwa ichafunga zvinotevera kumisikidzwa; Die-casting machine ine vacuum, choto chekuchengetedza kupisa chakashongedzerwa nehuwandu hwekukanda sisitimu, chigadzirwa chine rudzi rwekupfapfaidza system, kupfupisa nguva yekupfapfaidza, robhoti kutora zvikamu, slag bag, kodhi kucheka uye rimwe basa, yekupedzisira kucheka kune gate system; Iyo die-casting island inogona zvakare kukwidziridzwa kuitira otomatiki kuchenesa pasi pehupamhi hwepamusoro mamiriro.

1.2

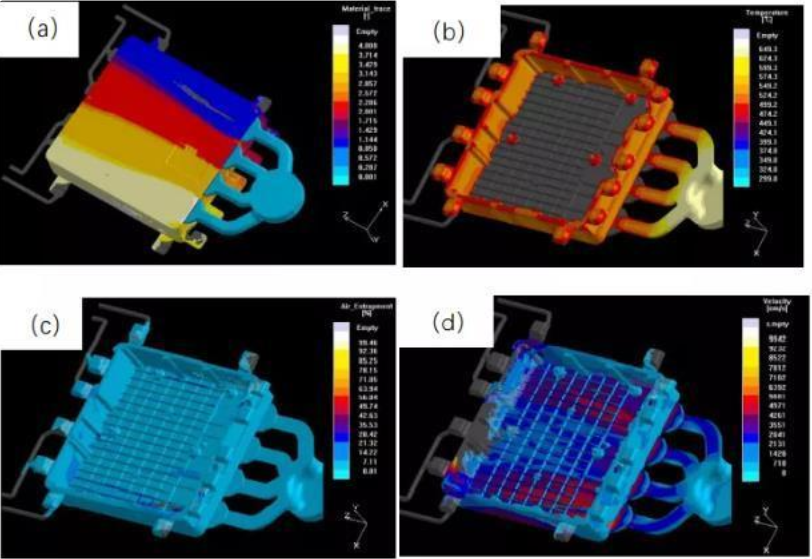

Kuongororwa kweCAE kunowedzera uye kunoshandiswa zvakanyanya muindasitiri yekufa, inomiririrwa nePROCAST, MAGMA, flow-3D, etc. Maererano nemigumisiro yekuverenga yekuzadza kuyerera uye kugovera kwevelocity, kuenzanisa kunogona kunyatsofanotaura kukanganisa kwakadai sekunyora, kuiswa uye kuzadza kwakashata, iyo inovandudza zvakanyanya goho uye inochengetedza mutengo une chinangwa. Icho chishandiso chinobatsira kwazvo kukurumidza uye nesainzi kugadzira iyo yese yekukanda system (gedhi, sprue uye mafashama tank, nezvimwewo) yekukandira kufa. Gadzirisa kukanda maitiro paramita, kuderedza huwandu hwekuyedzwa kwe mold, kuderedza kukanda mutengo, kunatsiridza mhando yechigadzirwa. CAE software yakashandiswa kuongororwa kwakawanda kwekuzadza, kusimba, porosity kugovera uye velocity kugovera mishumo

1.3 Kushandiswa kwevacuum die casting

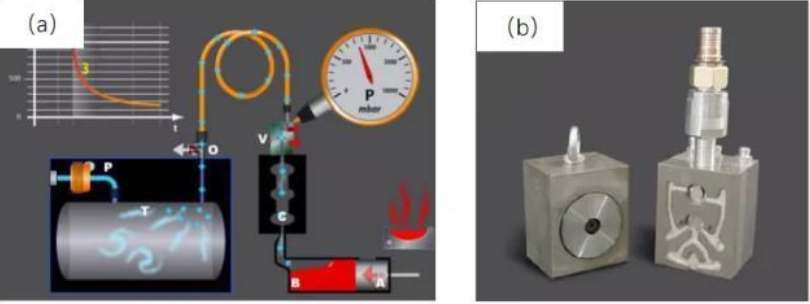

Nekuenderera mberi kwechigadzirwa chemhando yezvinodiwa, kushandiswa kwevacuum kugadzirisa dambudziko rekuzadza uye kusimba kwemhepo yekukanda kwakagadzirwa zvakanaka, uye vacuum valve inowanzoshandiswa, iyo inonyanya kushandiswa vacuum valve ine zvinotevera zvimiro. Mufananidzo 3 ndiyo dhiyabhorosi dhiyagiramu yevacuum valve. Kufanana neyakajairwa kufa yekukanda maitiro, mushure memvura yealuminium yapinda mukamuri, vacuumization inotanga kutanga. Zvino, kana muchina wekukanda kufa uchinge watanga nekumhanya, iyo kinetic simba remvura yealuminium inovimbwa nayo kubata chitubu ndiro yevhavhavhavha. Paunenge uchishandisa mechanical vacuum valve, inowanzovharwa paunenge uchipisa mold. Kana iyo preheating yapera, vacuum valve inogona kushandiswa chete kana kumhanya kwakanyanya uye kudzvanywa kwatangwa. Mechanical vacuum valve ine zvakanakira kushandiswa nyore, asi kugadzirisa kurongeka kwevacuum valve kwakakwira, uye mutengo wevacuum valve wakakwira. Mufananidzo 4 ndiyo dhizaini yedhizaini ye hydraulic vacuum valve. Nheyo ye mechanical vacuum valve yakafanana. Kana iyo punch inotanga, iyo vacuum inotanga, asi nheyo yekuvhara valve yekuvhara yakasiyana. Kana iyo hydraulic vacuum valve inowanzotangwa nekukurumidza, iyo mhando inotumirwa kune hydraulic system yevacuum valve panguva imwe chete, uye vacuum valve yakavharwa. Mutengo we hydraulic vacuum valve wakadzikira, asi zvinoda kuti iyo kufa casting process paramita uye mold dhizaini ienderane, zvikasadaro mvura yealuminium inofa ichikanda muvhavhavha inokonzeresa kuvharika.

2.Castings

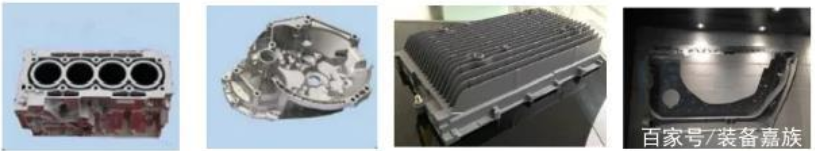

Parizvino, aluminium alloy die casting zvigadzirwa zvakakamurwa muzvikamu zvitatu zvichienderana nehuwandu. Chikamu chekutanga imotokari, mudhudhudhu, ganda rekufambisa injini inomiririrwa neinjini, silinda muviri uye zvichingodaro. Rudzi rwechipiri ndeye base station shell uye sefa ganda rinomiririrwa netiweki kutaurirana, uye yechitatu mhando chimiro chemuviri chine yakakwira mechanic kuita zvinodiwa. Sezvinoratidzwa mumufananidzo, ndeye yakajairwa aluminium alloy die casting product:

3. Mhedziso

Aluminium alloy ine yakakwirira chaiyo simba uye yakanaka corrosion kuramba, yakanakisa magetsi conductivity. Pasi penzvimbo yemagariro ekuchengetedza simba uye kuderedza kuburitsa uye girinhi kuchengetedza kwezvakatipoteredza, aluminium alloy die casting yakagadzira nekukurumidza muChina. Ndinotenda kuti munguva pfupi iri kutevera, zvigadzirwa zvealuminium alloy zvichave zvakasiyana. Iyo huru deformation iri muzvikamu zvinotevera; 1) Nekuvandudzwa kwezvigadzirwa, zvinofambisa kuvandudzwa kwezvinhu zvitsva zvealuminium alloy alloy, zvakadai se: high thermal conductivity, simba guru uye kusimba kwepamusoro; 2) mitsva yekukandira aluminium alloy zvinhu zvichave zvakare kutyaira kusimudzira kweiyo nyowani yekukanda tekinoroji, semi-solid die casting process, iyo yakakwira vacuum suction casting 3) kuvandudza tekinoroji ichapawo midziyo, zvinhu zvekubatsira zvinoisa pamberi pepamusoro zvinodiwa. , senge: hombe yekukanda kufa, kufa tembiricha muchina, kupfapfaidza midziyo, mold kuburitsa muchina unoenderana, vacuum muchina, inotonhora muchina, mold tembiricha yekudzora uye yekuona system, nezvimwe.

Nguva yekutumira: May-19-2022