Sarudza ku: Dual-clutch gearbox zvigadzirwa zvakanyorova zviviri-clutch gearbox, iyo goko rinotsigira rine clutch uye gearbox shell, iwo mabhomba maviri anogadzirwa neakanyanya kudzvanywa nzira yekukanda, mukugadzira chigadzirwa uye kugadzirwa kwakasangana nekuoma kwemhando yekuvandudza maitiro. , blank comprehensive qualified rate by about 60% 95% pakupera kwekukwira kusvika 2020 mazinga, Ichi chinyorwa chinopfupikisa mhinduro kumatambudziko emhando.

Wet dual-clutch transmission, iyo inoshandisa inovandudza cascade gear set, electro-mechanical shift drive system uye itsva electro-hydraulic clutch actuator. Iyo shell isina chinhu inogadzirwa neyekumanikidza kukanda aluminium alloy, ine hunhu hwehuremu huremu uye simba rakawanda. Kune hydraulic pombi, yekuzora mvura, pombi inotonhorera uye yekunze kutonhora sisitimu mubhokisi regiya, iyo inoisa kumberi kwepamusoro zvinodiwa pane yakazara mechanic kuita uye yekuisa chisimbiso kuita kwegoko. Iri bepa rinotsanangura maitiro ekugadzirisa matambudziko emhando akadai seganda deformation, mweya shrinkage gomba uye leakage pass rate iyo inokanganisa kupasa zvakanyanya.

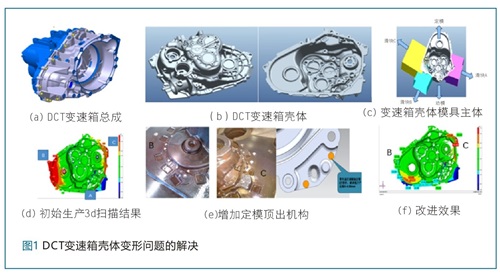

1,Solution ye deformation dambudziko

Mufananidzo 1 (a) pazasi,Iyo giya bhokisi rinoumbwa neakakwira-kumanikidza cast aluminium alloy gearbox dzimba uye clutch imba. Iyo inoshandiswa ndeye ADC12, uye yakakosha madziro ukobvu hunosvika 3.5mm. Iyo gearbox shell inoratidzwa mumufananidzo 1 (b). Saizi yekutanga ndeye 485mm (kureba) × 370mm (hupamhi) × 212mm (kureba), vhoriyamu i2481.5mm3, nzvimbo yakarongwa i134903mm2, uye huremu hwemambure hunosvika 6.7kg. Icho chikamu chakaonda-chakakomberedzwa chakadzika-cavity. Tichifunga nezvekugadzira uye kugadzirisa tekinoroji ye mold, kuvimbika kwekuumbwa kwechigadzirwa uye maitiro ekugadzira, mold yakarongedzwa sezvakaratidzwa mumufananidzo 1 (c), iyo inoumbwa nemapoka matatu emasiraidhi, inofamba mold (munzira yekunze. mhango) uye yakagadziriswa mold (mune nzira yemukati wemukati), uye iyo inopisa shrinkage rate yekukanda yakagadzirirwa kuva 1.0055%.

Chaizvoizvo, mukuita kwekutanga bvunzo yekukanda kufa, zvakaonekwa kuti saizi yechinzvimbo chechigadzirwa chakagadzirwa nekukandwa kufa kwakasiyana zvakanyanya nezvinodiwa zvekugadzira (dzimwe nzvimbo dzaive pamusoro pe30% kubva), asi saizi yekuumbwa yaive yakakodzera uye iyo shrinkage rate kana ichienzaniswa nehukuru chaihwo hwaienderanawo nemutemo we shrinkage. Kuti uwane chikonzero chechinetso, 3D scanning yeganda remuviri uye theoretical 3D yakashandiswa kuenzanisa nekuongorora, sezvakaratidzwa mumufananidzo 1 (d). Zvakaonekwa kuti base positioning nzvimbo ye blank was deformed, uye deformation uwandu hwaive 2.39mm munzvimbo B uye 0.74mm munzvimbo C. Nekuti chigadzirwa chakavakirwa paconvex point ye blank A, B, C yeinotevera. kugadzirisa bhenji yekumisikidza uye kuyerwa bhenji, deformation iyi inotungamira mukuyerwa, imwe saizi fungidziro kuA, B, C sehwaro hwendege, nzvimbo yegomba iri kunze kwekurongeka.

Kuongorora kwezvikonzero zvedambudziko iri:

① High pressure casting die dhizaini dhizaini ndechimwe chezvigadzirwa mushure mekudhonzwa, zvichipa chimiro kune chigadzirwa pane inoshanduka modhi, inoda mhedzisiro paiyo inoshanduka modhi yepakeji simba rakakura kupfuura masimba anoshanda pane yakagadziriswa mold bag yakasimba, nekuda kwe iyo yakadzika mhango yakakosha zvigadzirwa panguva imwe chete, yakadzika mhango mukati memacores pane yakagadzika mold uye yekunze mhango yakaumbwa pamusoro peinofamba mold zvigadzirwa kuti isarudze kutungamira kweiyo mold yekuparadzana apo ichazotambura kudhonza;

②Kune masiraidhi kuruboshwe, kuzasi uye kurudyi nzira dze mold, ayo anoita basa rekubatsira mukurovera kusati kwagadzirwa. Simba rerutsigiro diki riri kumusoro B, uye chimiro chese ndechekudzika mugomba panguva yekudziya kwekushisa. Izvo zvikonzero zviviri zviri pamusoro apa zvinotungamira kune yakakura deformation paB, inoteverwa naC.

Chirongwa chekuvandudza chekugadzirisa dambudziko iri ndechekuwedzera yakagadziriswa kufa ejection mechanism Mufananidzo 1 (e) pane yakagadziriswa inofa pamusoro. PaB yakawedzera 6 set mold plunger, ichiwedzera maviri akagadzika mold plunger muC, yakagadziriswa pini tsvimbo ndeyekuvimba nereset peak, kana ichifamba mold clamping ndege isa reset lever inoidzvanya muforoma, mold automatic die pressure inopera, musana. yeplate chitubu uye wobva wasundidzira pamusoro pepamusoro, tora danho rekusimudzira zvigadzirwa zvinobuda kubva kune yakagadziriswa mold, kuitira kuti uone offset deformation deformation.

Mushure mekugadzirisa mold, iyo deformation deformation inoderedzwa zvinobudirira. Sezvinoratidzwa muFIG.1 (f), deformations paB neC inonyatsodzorwa. Point B ndeye +0.22mm uye point C iri +0.12, iyo inosangana nezvinodiwa zveiyo blank contour ye0.7mm uye kuwana kugadzirwa kwakawanda.

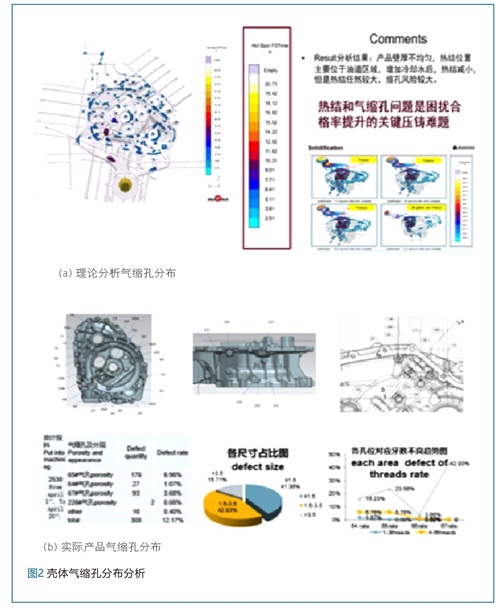

2, Kugadziriswa kwegomba shrinkage gomba uye kuvuza

Sezvinozivikanwa kune vese, high pressure casting inzira yekugadzira iyo iyo simbi yemvura inokurumidza kuzadzwa mukati mesimbi mold cavity nekuisa imwe kudzvanywa uye inoomesa nekukurumidza pasi pekumanikidzwa kuwana kukanda. Nekudaro, zvichienderana nehunhu hwekugadzirwa kwechigadzirwa uye kufa kukanda maitiro, kuchine dzimwe nzvimbo dzemajoini anopisa kana ane njodzi huru yemhepo shrinkage maburi muchigadzirwa, izvo zvinoenderana ne:

(1) Kudzvanya kunoshandisa kudzvanya kudzvanya simbi yemvura mugomba nekumhanya kukuru. Iyo gasi mukamuri yekumanikidza kana mold cavity haigone kuburitswa zvachose. Aya magasi anobatanidzwa musimbi yemvura uye anozopedzisira avepo mukukanda nenzira yemapores.

(2) Kunyungudika kwegasi mumvura aruminiyamu uye yakasimba aluminium alloy yakasiyana. Mukuita kwekusimba, gasi rinodzivirirwa nemhepo.

(3) Iyo simbi yemvura inoomesa nekukurumidza mugomba, uye kana pasina kudya kunoshanda, zvimwe zvikamu zvekukanda zvinoburitsa shrinkage cavity kana shrinkage porosity.

Tora zvigadzirwa zveDPT zvakatevedzana zvakapinda muchiratidziro chekushandisa uye diki yekugadzira batch nhanho semuenzaniso (ona Mufananidzo 2) : Chiyero chekuremara kwekutanga kwemhepo shrinkage gomba rechigadzirwa chakaverengerwa, uye chepamusoro chaive 12.17%, pakati peiyo mhepo. shrinkage gomba rakakura kupfuura 3.5mm rakaverengera 15.71% yehurema hwakakwana, uye mhepo inodzikira gomba pakati pe1.5-3.5mm yakaverengera 42.93%. Aya maburi emhepo aidzika zvakanyanya mune mamwe maburi ane shinda uye nzvimbo dzekuvharira. Izvi zvinokanganisa zvinokanganisa simba rekubatanidza bhoti, kusimba kwepamusoro uye zvimwe zvinoshanda zvinodiwa zvezvimedu.

Kugadzirisa matambudziko aya, nzira huru ndedzinotevera:

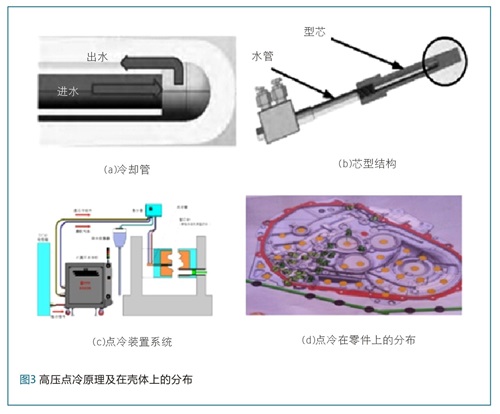

2.1SPOT COOLING SYSTEM

Inokodzera kune imwechete yakadzika mhango zvikamu uye hombe dzepakati zvikamu. Iyo inoumba chikamu chezvivakwa izvi inongori mashoma mashoma makomba kana yakadzika mhango chikamu chekukweva kwepakati, nezvimwewo, uye mashoma mold anoputirwa nehuwandu hwakawanda hwearuminiyamu yemvura, zviri nyore kukonzera kupisa kwe mold, zvichikonzera kunamira. mold strain, kupisa kunopisa uye kumwe kukanganisa. Naizvozvo, zvinodikanwa kumanikidza kutonhora mvura inotonhorera panzvimbo yekupfuura yeyakadzika cavity mold. Chikamu chemukati chemukati chine dhayamita yakakura kupfuura 4mm inotonhodzwa ne 1.0-1.5mpa high-pressure mvura, kuitira kuti ive nechokwadi chokuti mvura inotonhorera inotonhora uye inopisa, uye matishu akapoteredza epakati anogona kutanga kusimba uye kuumba dense layer, kuitira kuderedza shrinkage uye porosity maitiro.

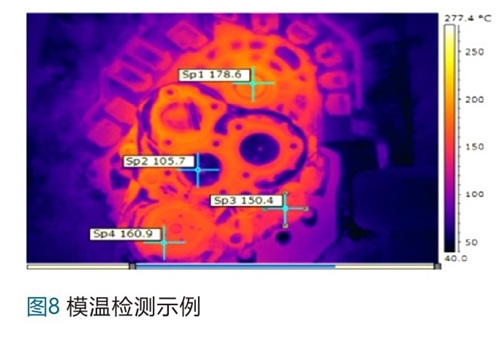

Sezvinoratidzwa muMufananidzo 3, yakasanganiswa nenhamba yekuongorora dhiyabhorosi yekuenzanisa uye zvigadzirwa chaizvo, iyo yekupedzisira poindi yekutonhora marongero yakagadziridzwa, uye iyo yepamusoro-yekudzvanya nzvimbo yekutonhora sezvakaratidzwa muFigure 3 (d) yakaiswa pane mold, iyo yakanyatso kudzora. tembiricha yechigadzirwa munzvimbo inopisa yekubatana, yakaziva kutevedzana kwekusimba kwezvigadzirwa, zvakadzikamisa kugadzirwa kwemaburi ekuderera, uye ive nechokwadi chechiyero chakakodzera.

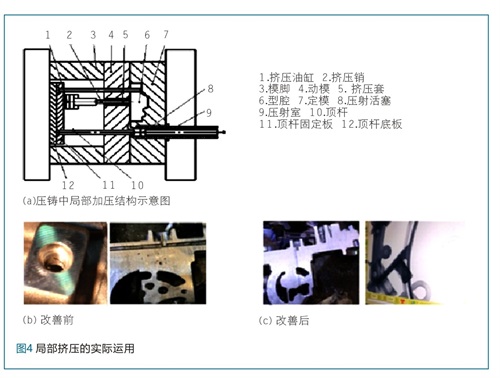

2.2Local extrusion

Kana hukobvu hwemadziro echigadzirwa chekugadzira dhizaini isina kuenzana kana paine mahombe anopisa anopisa mune dzimwe nzvimbo, shrinkage maburi anowanzo kuoneka muchikamu chekupedzisira chakasimba, sezvakaratidzwa muFIG. 4 (C) pazasi. Iyo shrinkage maburi mune izvi zvigadzirwa haigone kudzivirirwa nekufa casting process uye kuwedzera nzira yekutonhora. Panguva ino, extrusion yemunharaunda inogona kushandiswa kugadzirisa dambudziko. Chikamu chekumanikidza chimiro dhayagiramu sezvakaratidzwa mumufananidzo 4 (a), iyo yakaiswa yakananga muhumburumbira, mushure mesimbi yakanyungudutswa ichizadza muforoma uye yakaomeswa zvisati zvaitika, kwete zvachose mune semi-yakasimba simbi mvura mugomba, iyo pakupedzisira. solidification gobvu madziro ne extrusion tsvimbo kumanikidza kudyisa kudzikisa kana kubvisa kwayo shrinkage cavity hurema, kuitira kuwana yakakwirira mhando yekukanda kufa.

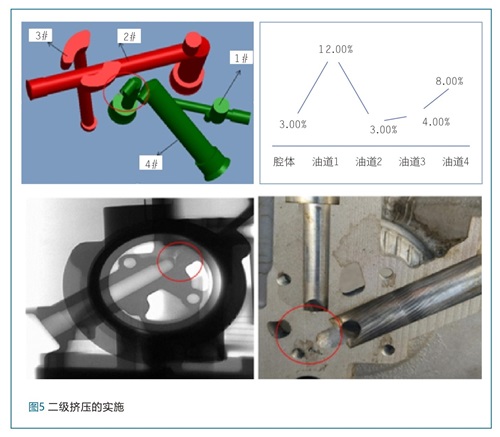

2.3The yechipiri extrusion

Chikamu chechipiri che extrusion ndechekuisa kaviri sitiroko cylinder. Sitiroko yekutanga inopedzisa kuumbwa kwechikamu chekutanga gomba rekukanda, uye kana iyo aluminium yemvura yakatenderedza musimboti yakasimbiswa zvishoma nezvishoma, yechipiri extrusion chiitiko chinotangwa, uye kaviri mhedzisiro yepre-casting uye extrusion inozoitika. Tora iyo giya bhokisi dzimba semuenzaniso, chiyero chakakodzera cheyedzo-yakasimba gasi bvunzo yegiya bhokisi rekugara muchikamu chekutanga chepurojekiti iri pasi pe70%. Kugovaniswa kwezvikamu zvekuvuza kunonyanya kupindirana kwemafuta ndima 1# uye mafuta ndima 4# (denderedzwa dzvuku mumufananidzo 5) sezvaratidzwa pazasi.

2.4KUKANDA RUNNER SYSTEM

Iyo yekukanda sisitimu yesimbi die casting mold inzira inozadza gomba rekufa casting modhi ine yakanyungudutswa simbi yemvura mukamuri yekutsikirira yemuchina wekukanda kufa pasi pemamiriro ekupisa kwakanyanya, kudzvanywa uye kumhanya kwakanyanya. Inosanganisira mumhanyi akatwasuka, mumhanyi wemuchinjikwa, mumhanyi wemukati uye anofashukira exhaust system. Ivo vanotungamirwa mukuita kweiyo yemvura simbi inozadza mhango, iyo inoyerera nyika, velocity uye kudzvanywa kweyemvura simbi kutamiswa, mhedzisiro yekubuda uye kufa mold inotamba yakakosha mune senge thermal equilibrium mamiriro ekutonga uye mutemo, saka. , gating system inosarudzwa kufa kukanda pamusoro pemhando pamwe chete nechinhu chakakosha chemukati microstructure state. Dhizaini uye kupedzisa kwekudira sisitimu inofanira kunge yakavakirwa pamubatanidzwa wedzidziso uye maitiro.

2.5ProcessOoptimization

Die casting process ibasa rinopisa rinosanganisa uye rinoshandisa muchina wekukanda kufa, kufa kwekufa uye simbi yemvura zvinoenderana neyakafanosarudzwa maitiro maitiro uye maparamendi ekugadzirisa, uye inowana iyo yekukanda kufa nerubatsiro rwemagetsi drive. Zvinotora marudzi ese ezvinhu kutariswa, senge kudzvanywa (kusanganisira jekiseni simba, jekiseni chairo kudzvanywa, simba rekuwedzera, mold yekuvhara simba), jekiseni kumhanya (kusanganisira punch kumhanya, yemukati gedhi kumhanya, nezvimwewo), Kuzadza kumhanya, nezvimwewo) , tembiricha dzakasiyana-siyana (kunyunguduka tembiricha yesimbi yemvura, kufa kukanda tembiricha, mold tembiricha, nezvimwewo), nguva dzakasiyana (yekuzadza nguva, kumanikidza kubata nguva, mold kuchengetedza nguva, nezvimwewo), zvinopisa zvivakwa zve mold (kupisa kwekushisa, kupisa. chiyero chesimba, tembiricha gradient, etc.), kukanda zvivakwa uye zvinopisa zvimiro zvesimbi yemvura, etc. Izvi zvinotora chinzvimbo chinotungamira mukukandira kufa, kumhanya kwekuzadza, kuzadza hunhu uye kupisa zvinhu zve mold.

2.6Kushandiswa kwemaitiro matsva

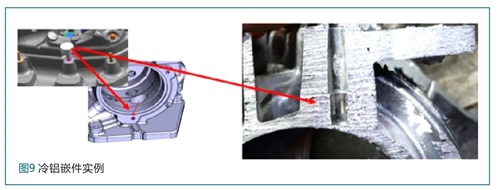

Kuti ugadzirise dambudziko rekuvuza rezvikamu zvakasununguka mukati mezvikamu zvegearbox shell, mhinduro yekutonhora yealuminium block yakashandiswa kupayona mushure mekusimbiswa nemativi ese ekupa uye kudiwa. Iko ndiko kuti, chidimbu chealuminium chinotakurwa mukati mechigadzirwa chisati chazadza, sezvinoratidzwa mumufananidzo 9. Mushure mekuzadza nekusimbisa, iyi inopinza inoramba iri mukati mechikamu chechikamu kugadzirisa dambudziko rekuderera kwenzvimbo uye porosity.

Nguva yekutumira: Sep-08-2022